COOLER SETUP

Remote draft beer systems require regulated gas pressure to transport beer from the keg cooler to the bar area. Beer pumps are recommended to assist in the dispensing process if a beer system is pumping over 100'. The brewer specifies individual beer pressures, and pumps help maintain the recommended pressure allowing the beer to travel greater distances. Easybar cooler kit systems include draft beer equipment such as foam protection devices (FOBs) and two single gauge regulators to ensure proper pressure application.

Cooler Setup Components

Draft Beer Pump

Beer pumps are designed for dispensing draft beer from a keg cooler. Gas pressure is applied to the pump and the beer individually, optimizing the pressure for the system and maximizing the distance capability while keeping the recommended pressure stable.

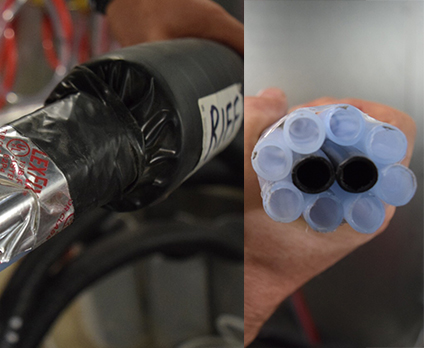

Draft Beer Tubing

Easybar bundled beer product lines are sealed in an extruded jacket with moisture wrap and are further insulated with 1/2″ foam. These measures ensure that all beer lines stay glycol chilled on the way to the beer faucet for dispensing.

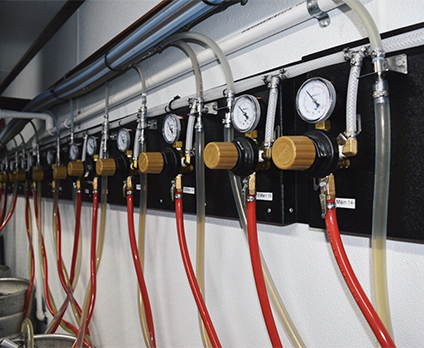

Draft Beer Regulator

Beer regulators control the pressure from the gas cylinder to the keg coupler. The pressure regulator contains a manual-adjusting knob to regulate the amount of pressure supplied to the keg. A properly functioning regulator is critical in maintaining the proper level of CO2 in the beer as too much CO2 pressure may cause foaming problems and too little CO2 pressure may cause flat tasting beer.

Foam Control Detector

FOB detectors sense an empty keg or other foaming issues and shut down the flow of beer in the line. FOBs allow the beer lines to remain full when the keg empties. Since there is no need to re-fill the beer line when attaching a new keg, waste is reduced and the number of glasses served per keg is maximized.

BEER CHILLERS

These systems ensure that all beer lines are properly chilled from the keg cooler to the tap, guaranteeing that beer is served at the perfect temperature to maintain flavor and prevent flat or foamy pours. For most types of beer, maintaining a temperature of 38 degrees Fahrenheit throughout the beer run ensures the beer will maintain the level of carbonation that was created during the brewing process. If beer chillers do not keep the beer cold all the way to the faucet, the quality of the beer will suffer greatly. We realize that every beer and every brewer are different, and beer chillers accommodate the various serving temperatures in the craft beer market.

Features

- Beer chillers are available in 1⁄2 HP, 3⁄4 HP, 1 HP, and 1 1⁄2 HP

- Beer chiller units are offered in both air-cooled and water-cooled models

- Beer chillers can be equipped with either single or dual pumps

- All chillers include a digital temperature gauge and digital temperature adjustment

- Units are built to commercial standards